Wolfzter's Custom Rod Shoppe

Tuesday, June 22, 2010

Tuesday, January 27, 2009

New Project - Brian K's Cobra

.jpeg) This is the 'Coolest' Cobra I have ever built...it can't get better than this! Double-click on the pics to get the full size.

This is the 'Coolest' Cobra I have ever built...it can't get better than this! Double-click on the pics to get the full size.You are probably wondering what makes it so Cool?Let me first tell you a little story. One day the phone rings, a guy is on the other end asking..."What will $35,000 get me?" Well, we can offer you a complete kit less driveline for around that price. The guy says..."I can get a running Cobra for $35k" and so...

Some time later the phone rings again. Hey, it's the guy again and his name is Brian...he needs a little cosmetic work done to his Cobra. Brian brings the car to the shop along with a list of things he would like to get done. I had a good look at the project, Big Block Chev, Automatic, cramped cockpit, cheapness everywhere but very shiny paint!

.jpeg)

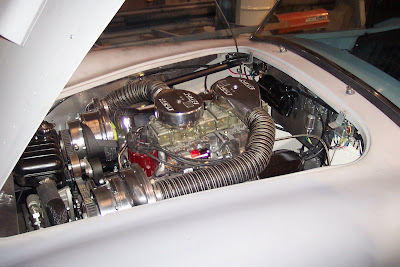

One thing led to another and we ended up with a complete tear down and redo. The end result was awesome...428CJ, 5-Speed, New Leather Interior, Shelby Gauges, New Paint and the list goes on. We had a bucket of washers left over from the rebuild...the original builder used these to 'Shorten' his bolts. It became an inside joke between Brian and I.

Now Brian is smiling big time! OK, so it cost a few bucks but finally the sting of buying a S#!t Box has gone away. The guys at the Club don't even recognize the car..."Hey, who's Cobra is that?...It's Brian's...No Way!" A couple of months later at a local show some dude offers Brian $80k for his Cobra. Now what? Sell it, we'll build a new one.

A valuable lesson: You get what you pay for!

.jpeg) Brian says, "I want to build the best possible...on a budget of course." So the journey begins...The pictures posted show the second car we built for Brian, Our Multi-tube chassis with dropped seating for comfort, Wilwood Brake upgrades, Custom IRS using the Ford 8.8, TKO 5-Speed, 427 LeMans Engine with 48IDA Weber Carbs, Original Trim and Parts...altogether an authentic replica effort without the price of an 'Original'. Some smart shopping on the

Brian says, "I want to build the best possible...on a budget of course." So the journey begins...The pictures posted show the second car we built for Brian, Our Multi-tube chassis with dropped seating for comfort, Wilwood Brake upgrades, Custom IRS using the Ford 8.8, TKO 5-Speed, 427 LeMans Engine with 48IDA Weber Carbs, Original Trim and Parts...altogether an authentic replica effort without the price of an 'Original'. Some smart shopping on the .jpeg) Parts to keep the cost down and things are shaping up nicely. The car is back from the Paint Shop and looking good.

Parts to keep the cost down and things are shaping up nicely. The car is back from the Paint Shop and looking good. .jpeg) All of the parts were fitted before final assembly and things are literally bolting together themselves. We test-fired the engine and quickly found out that the carbs were set for Drag Racing...time to tune these puppies for street use! Let the Games begin.

All of the parts were fitted before final assembly and things are literally bolting together themselves. We test-fired the engine and quickly found out that the carbs were set for Drag Racing...time to tune these puppies for street use! Let the Games begin.Anybody know of a good Ferrari Mechanic? The car went from one shop to another, no luck! One dude gave Brian a bill for $14,000 for tuning the Webers and then told him ..."Go away, that's the best I can do!"

Well, the Judge sided with Brian...and now...finally someone that knows what to do managed to tune Brian's car. There are a lot of unscrupulous people out there just waiting to work on your

car and then...F^@k you out of some money...when they see a Cobra they figure you're rich...Watch out!

car and then...F^@k you out of some money...when they see a Cobra they figure you're rich...Watch out!The Car is now at the paint shop getting the damaged fixed from the 'Dude'...I wish I could post his name but I can tell you that it rhymes with 'Redneck'...Beware!

Spring is just around the corner and this story will have a happy ending after all! I will be posting some Video Clips of our driving experience for you fans out there...stay tuned!

God Bless

Wolfzter

Friday, January 23, 2009

New Project - Gary P's Cobra

.jpeg)

.jpeg)

.jpeg)

Just to keep you Guys informed of what's going on in our shop these days, I'll be posting the progress on our Friend's cars as we go. Double-click on the pics to get the full size!

This one was originally built for me as a replacement for our Demo...life began as a simple idea. You are probably wondering about the paint scheme...

'Wow, looks a little wild!'You are absolutely right, my problem is that I just can't build ordinary looking stuff. Over the years of building these cars, I accumulated a lot of 'Spare Parts' and stuff I bought for a Future use...I decided that now was the time to round up everything and see what we have.

.jpeg) I departed from our standard frame and thought to try a simpler platform design using Round Tube Main Rails, a simple Live Axle and basically Tubular Mustang II Front Suspension.

I departed from our standard frame and thought to try a simpler platform design using Round Tube Main Rails, a simple Live Axle and basically Tubular Mustang II Front Suspension.Now for the interesting part, what do I use for an engine? Well, I bought a 4.6 SOHC last year from a Police Interceptor...the Cop was chasing a Camaro around Abbotsdford and managed to spin a Rod Bearing in the chase! Not good for the Police...Lucky for the Dude in the Camaro! So...one too many Beer and I got a smart idea. Hey, lets put some Webers on it...Ebay to the rescue. I fabricated some manifolds and glass-beaded them to get a 'Casting Look'. Next was the Ignition, better to run a simple distributor driven off the Cam. The Cast Aluminum Valve Covers helped out to get a positive register for the adaptor. I used a MSD Billet Distributor and machined down the body, cut a slot into the shaft and designed a drive button to mount on the Left Hand Cam Gear. Everything lined up perfectly and rotated without binding. The rest of the engine got the treatment...Ross Flat Top Forged Pistons, SCAT H-Beam Rods, Tumble Porting to the Heads, new everything.

The tranny was procured from Higgins Racing as a race upgraded T45 and the Hydraulic Throw-out bearing completed the driveline.

Headers and sidepipes were all built on assembly and sent out for Ceramic Coating. Things were shaping up nicely and the car was coming together as planned.

.jpeg) The tricky part was to stuff this thing into the engine bay. The Fiberglass footboxes were modified with extra large wedges to clear the massive Valve Covers and then finished off in White Epoxy.

The tricky part was to stuff this thing into the engine bay. The Fiberglass footboxes were modified with extra large wedges to clear the massive Valve Covers and then finished off in White Epoxy..jpeg) The body was prepped, primed and sent to the Paint Shop along with the instructions...here is a picture of what I got back. Yeah, it definitely looks wild but grows on you the more you look at it.

The body was prepped, primed and sent to the Paint Shop along with the instructions...here is a picture of what I got back. Yeah, it definitely looks wild but grows on you the more you look at it. I guess the Cobra in general is not an 'Ordinary' Ride anyhow...

Like any other guy planning to build a Cobra, I also had a budget in mind. Try to get the highest 'Cool Factor' for the least amount of Money, Right? Sure...but maybe we'll add this little gadget, and then that one, Oh and it also needs this...you can see where this is going.

In the end, it was money well spent and as the project comes together the purse strings loosen.

Then I met Gary! He is your typical dude who (like me) has been drooling over these cars for most of his adult life..."One of these days"... and then the day comes. We connected through a mutual friend of ours, also a proud Cobra owner, and hooked up for a meeting. Gary says..."Wow, I saw the car already from the road"...and then began the love affair. We went over some of the details of the car, the extras that distinguish a Good Cobra replica from the rest. Gary seemed like a real nice and sensible guy and we both agreed that the Weber engine would not be suitable to what he had in mind for the car. He says..."I need a car I can into and just drive". Well, reading between the lines that spells 'Reliability and Durability'.

Enter the 351 Cleveland engine. I happen to have a '70 HO motor that was removed from a Torino GT, along with the new Edelbrock Aluminum heads and some serious Performance upgrades we can build an excellent replacement motor.

Enter the 351 Cleveland engine. I happen to have a '70 HO motor that was removed from a Torino GT, along with the new Edelbrock Aluminum heads and some serious Performance upgrades we can build an excellent replacement motor. So this is where we are at. With Spring approaching, the new driveline is being fitted and new custom headers fabricated. I will be posting some progress pics as we go and will also be posting a Video Clip of the initial starting. This is the fun Part! Make sure your guys check back regularly and have a look...We will not disappoint you!

So this is where we are at. With Spring approaching, the new driveline is being fitted and new custom headers fabricated. I will be posting some progress pics as we go and will also be posting a Video Clip of the initial starting. This is the fun Part! Make sure your guys check back regularly and have a look...We will not disappoint you!God Bless

Wolfzter

Monday, January 19, 2009

The 427 Cobra Years....Now!

After 7 years in Chilliwack it was time to move once again. The added headache of having a secondary Rental House on the property put the 'Melodrama' over the top! Tania and I found a nice place in Harrison, older home on 1-acre and no shop! But hey, there was no Rental House anymore! I just needed to build a shop and clean up the joint a little, dead simple! Double-click on the pics to get the full size.

After 7 years in Chilliwack it was time to move once again. The added headache of having a secondary Rental House on the property put the 'Melodrama' over the top! Tania and I found a nice place in Harrison, older home on 1-acre and no shop! But hey, there was no Rental House anymore! I just needed to build a shop and clean up the joint a little, dead simple! Double-click on the pics to get the full size.Six Months of hard labor and the Shop is up. The view is truly majestic and walking to work every morning is a blast! I had taken a little hiatus lasting almost two years...getting away from the whole car thing and trying to heal from the burn-out factor. I basically went AWOL for a while and started to get the old itch again...Oh Oh! Tania is once again getting nervous and wondering...

"Now what is he up to?"That was a good question and one that a lot of our old comrades were also wondering. I started easing into the work again. I had a contract to build some composite Aircraft Parts for a local Kit Plane Manufacturer and the Wireless Wave display units were still bringing in the money to live. But somehow, that was not nearly as satisfying as building cool cars. I started work on our Aluminum Car and got inspired again! I started thinking about producing a 'New' kit based on the 'Old' ideas...it doesn't get more authentic than the real thing and I have one laying around.

So the design work began and is nearly complete to offer on the market. I will be posting our new concept this Spring for you Guys to have a look at, and give me some of your thoughts on. I think you'll like it and I aim to make it as affordable as possible which is something not really being offered by anyone yet...

I learned in my many years in this business that it is important to have a good working relationship with our customers. This makes things easy for everyone. I worked myself to exhaustion in the past and my customers were no always happy. Things simply did not happen fast enough, and how could they? One guy building Kits, Turn-key Cars and other types of work simply can not keep up. I have single-handedly created a whole fleet of cars over the years, but nowhere near the numbers that some of the larger USA-based companies claim.

I learned in my many years in this business that it is important to have a good working relationship with our customers. This makes things easy for everyone. I worked myself to exhaustion in the past and my customers were no always happy. Things simply did not happen fast enough, and how could they? One guy building Kits, Turn-key Cars and other types of work simply can not keep up. I have single-handedly created a whole fleet of cars over the years, but nowhere near the numbers that some of the larger USA-based companies claim. That's OK by me...I am satisfied in building smaller numbers but higher-quality cars.

I'm taking a more informal approach to doing business these days! Taking the time to get to know a person a little before agreeing to get into a long term business relationship is wise. I have had the displeasure of dealing with a few &$%#@! over the years (If you are reading this then you know who you are!) and this will never happen again, for sure! Nice Guys are Welcome anytime at Wolfzter's Custom Rod Shoppe!

I'm taking a more informal approach to doing business these days! Taking the time to get to know a person a little before agreeing to get into a long term business relationship is wise. I have had the displeasure of dealing with a few &$%#@! over the years (If you are reading this then you know who you are!) and this will never happen again, for sure! Nice Guys are Welcome anytime at Wolfzter's Custom Rod Shoppe!The 427 Cobra Years...The Designs

I quickly learned that it takes more than just a Cobra Body mold to be in the business of building these cars! My friend Kim dropped off an old Jig Table he had rusting away in his backyard..."You can use this more than me." he said. Double-click on the pics to get the full size.

I quickly learned that it takes more than just a Cobra Body mold to be in the business of building these cars! My friend Kim dropped off an old Jig Table he had rusting away in his backyard..."You can use this more than me." he said. Double-click on the pics to get the full size.My Dad's car finally was certified with the understanding that I never bring them another Frame like that to them again! Well, it was actually built on spec to a well-known USA-based Cobra Shop...I won't say which one.

Well, I now needed to design my own Chassis...but what type? Rectangular or Round Tube, Platform, Multi-tube or Backbone? Too many choices...all kinds being offered in the industry, where would mine fit in? I had a lot of complaints from guys over 6-foot tall that the Cobra was Uncomfortable and difficult to drive safely, so an idea was born. Why not drop the seating area down to the bottom of the frame rail...I could gain 3-inches depth right there. A lot of the manufacturers in the USA were actually altering the body shape to do this...That was not an Option here! Simply dropping the floor section around the pedals was also 'Cheesy' and unacceptable. It seems that my idea may be a good one...and it was! The picture above shows our first generation frame with dropped Steel Floor Pans and Welded Aluminum Foot Boxes. Although functional, this Frame still needed some work...

Well, I now needed to design my own Chassis...but what type? Rectangular or Round Tube, Platform, Multi-tube or Backbone? Too many choices...all kinds being offered in the industry, where would mine fit in? I had a lot of complaints from guys over 6-foot tall that the Cobra was Uncomfortable and difficult to drive safely, so an idea was born. Why not drop the seating area down to the bottom of the frame rail...I could gain 3-inches depth right there. A lot of the manufacturers in the USA were actually altering the body shape to do this...That was not an Option here! Simply dropping the floor section around the pedals was also 'Cheesy' and unacceptable. It seems that my idea may be a good one...and it was! The picture above shows our first generation frame with dropped Steel Floor Pans and Welded Aluminum Foot Boxes. Although functional, this Frame still needed some work...

The second generation was more streamlined and offered a custom-designed IRS as well. Instead of the welded Foot Boxes we now went with formed Rivet-on Aluminum Panels and Floor Pans...Much Better!

The end result was a Nice Looking, Rigid and Light Weight Frame and our Customers loved it!I also pride myself in claiming an original design. I did not need to copy anyone's design and call it my own, like so many of the other guys do that I came across.

The shop is starting to look like a real Production now, Customers, Prospects, Enthusiast and Friends dropping by regularly...it's a real 'Guy Hang-Out' now! A few Articles, Write-ups, Car Shows and most important of all 'Word of Mouth' are starting to produce results. Our Cars are cleaning up at the shows in both Canada and the USA.

Our reputation was beginning to grow...Affordable, Authentic, Detailed, Innovative, Handled...

The cars just 'Looked' and 'Felt' right!Tania had quit her job to retire at our Cobra Shop, running errands, answering the phone and chatting with our patrons! We stayed in Langley for about 6 Years and then decided to move the operation to Chilliwack, onto our own property and a much Larger shop. I could now spend more time 'playing' around with the cars. But then,

If it works, then don't change it, Right?Not around here! Not being quite satisfied with what we are using, I needed to make the car just a little more authentic and changed the upper tubular structure, exposed the Rollbar fully and tooled up some Fiberglass Foot Boxes. The IRS also got the treatment and now looked and worked more like the real thing! Most of our customers were now demanding 427 and 428 Engines, Pin-Drive Wheels, IRS Suspension and Original Cobra parts. This newly-engineered Chassis really did the trick! We now had a truly unique and sought after Kit. We tested the system repeatedly with 600-700 HP Engines, 514, 488 FE Strokers, Twin-Blown 427 and the list goes on. All held together at the brutality of the Owners heavy Feet...

.jpeg)

I have always worked on my own in our shop. It was easier to control the quality of the work and I didn't have to babysit employees...or I would have ended up behind a desk and managing a business. I decided I needed to work my business instead. This was not without consequence, I was working 10-12 hour days and mostly 7 days a week. Burn-out was just around the corner...

Friday, January 16, 2009

Project 'Porsche Midlife Crisis'...

Well Guys, Midlife Crisis gets all of us sooner or later (Pity the Wives and Girlfriends!)...the trick is how to manage it without getting hurt, broke or both! I figured the safe (and cheaper) bet is a cool car. The first 'Crisis' hit at around 29...Alright already, quit laughing! In a moment of supreme foolishness it hit me...'I gotta get me a 911 Porsche before I turn 30'...after all it's downhill from there. This is a picture of the real one I took at the Sinsheim Autotechnik Museum in Germany, very close to Karlsruhe where I was born. This museum has the largest exhibition of very rare and expensive automobiles, a real treat to go and check out. Double-click the pics to get the full size.

Well Guys, Midlife Crisis gets all of us sooner or later (Pity the Wives and Girlfriends!)...the trick is how to manage it without getting hurt, broke or both! I figured the safe (and cheaper) bet is a cool car. The first 'Crisis' hit at around 29...Alright already, quit laughing! In a moment of supreme foolishness it hit me...'I gotta get me a 911 Porsche before I turn 30'...after all it's downhill from there. This is a picture of the real one I took at the Sinsheim Autotechnik Museum in Germany, very close to Karlsruhe where I was born. This museum has the largest exhibition of very rare and expensive automobiles, a real treat to go and check out. Double-click the pics to get the full size. So I found this old, rusty, over-priced bucket and started planning...on a beer budget. Still working for the man, punching the clock for a modest wage, I started wondering..."Just how is this going to happen?" These aren't the cheapest cars to rebuild let alone modify, so I'll need to do all or most of the work myself to save the money. Makes sense...

So I found this old, rusty, over-priced bucket and started planning...on a beer budget. Still working for the man, punching the clock for a modest wage, I started wondering..."Just how is this going to happen?" These aren't the cheapest cars to rebuild let alone modify, so I'll need to do all or most of the work myself to save the money. Makes sense...After a lot of looking around at what is out there, I seriously considered buying a Turbo Flare, Bumper and Whale Tail kit and be done with it. But then...it's been done before and nothing special in the end. No solution for a serious Midlife at 30! No, I think I need to do something unique...like the new 959 they sold in Europe...Yeah! Between the old rust bucket in the garage, pictures and a detailed model I was able to draw some scaled proportions of the beast. No one was building anything like this yet and I would be the first dude on the block with a real neat 911.

Two weeks later, there sat my over-priced 'investment', stripped down to the bare shell and parts strewn all over the Garage. I noticed the floorboards must have been an option on this car because there weren't any! How am I going to explain myself? My Wife Tania started wondering if she had married a Fool...I started to wonder myself. At this point there was too much at stake to bail out, quit or make excuses so...

Two weeks later, there sat my over-priced 'investment', stripped down to the bare shell and parts strewn all over the Garage. I noticed the floorboards must have been an option on this car because there weren't any! How am I going to explain myself? My Wife Tania started wondering if she had married a Fool...I started to wonder myself. At this point there was too much at stake to bail out, quit or make excuses so... let's get busy!After the initial shock had worn off and the depression was subsiding, it was time to strip the old paint off the shell and the parts. This proved to be risky 'cause the paint was the only thing holding the car together! The Aircraft Paint Stripper just sat there and mocked me...Tania was shaking her head in disgust and both the car and neighbors were chuckling. The situation started to suck...Alright then, a 36-Grit Sanding Disc and Mini-Grinder should do the trick, and it did.

Scratch-made metal panels, inexpensive VW Floorpans (swapped Right to Left) and my trusty little plug-in MIG took care of the rusted through panels. With the new steel in place, things didn't look so bad anymore and I started to gain confidence and enthusiasm again.

Scratch-made metal panels, inexpensive VW Floorpans (swapped Right to Left) and my trusty little plug-in MIG took care of the rusted through panels. With the new steel in place, things didn't look so bad anymore and I started to gain confidence and enthusiasm again.The rust damage was the most severe I had ever encountered in my years of 'Rustorations'...this thing took the cake. The car originated from Alberta and the severe salt corrosion was evident. Not just non-existent floorboards but also Left Hand Front Fender inner, Front Suspension lower Cross Member, most of the Engine bay and the Rear Seat area as well. The rust damage was so severe that even the inside Dash steel was rusted through in places. Not a whole lot of steel for the money...

It was now time to start shaping the 959 body work. I bought a pick-up truck load of reject Urethane Foam Sheets from a manufacturer for a case of beer...Good deal! I started by cutting and gluing (using a Hot Melt Glue gun) sections of Foam to the body shell until I got the rough shape of the panel I was working on. The tops of the fenders were shaved and re-curved to droop like the original car before building up the fender flares. This is one of the few details that were attended to in building a high-quality replica.

It was now time to start shaping the 959 body work. I bought a pick-up truck load of reject Urethane Foam Sheets from a manufacturer for a case of beer...Good deal! I started by cutting and gluing (using a Hot Melt Glue gun) sections of Foam to the body shell until I got the rough shape of the panel I was working on. The tops of the fenders were shaved and re-curved to droop like the original car before building up the fender flares. This is one of the few details that were attended to in building a high-quality replica.Tania soon noticed one of her favorite Kitchen Knives was missing...Oops! Good thing that was the only thing she noticed...

The cute kid in the picture is our daughter Jessica, now already 22 years old and moved out. I once had young children and a Minivan...didn't slow down the car dreams one bit!

Using the knife, Bodyfile, Sanding Block and Flexboard the body started taking the desired shape. When the curves of 'The Mistress' were just right, it was time to 'Skin' the bodywork with a single layer of 2-oz. Fiberglass Matt. This gave me a solid working surface onto which the body filler was troweled and sanded to the final finish. Most of the rough shaping (to Foam and Filler) was done with 40-Grit paper. The finer work was then done with good quality 100-Grit paper and left. The High-Solids Primer will easily fill the sanding scratches during the final blocking stage.

Using the knife, Bodyfile, Sanding Block and Flexboard the body started taking the desired shape. When the curves of 'The Mistress' were just right, it was time to 'Skin' the bodywork with a single layer of 2-oz. Fiberglass Matt. This gave me a solid working surface onto which the body filler was troweled and sanded to the final finish. Most of the rough shaping (to Foam and Filler) was done with 40-Grit paper. The finer work was then done with good quality 100-Grit paper and left. The High-Solids Primer will easily fill the sanding scratches during the final blocking stage. The Primer was applied after most of the deep scratches and Pin-holes were filled with Polyester Putty and final-sanded to 100-Grit. The panels can now be cut to their Bolt-On dimensions. More filling and sanding to get the Mounting Flanges and Returns shaped and once again Primed. A guide coat is applied and final blocking is done with 320-Grit paper to all of the parts. The Pin-holes were thoroughly filled so that virtually none remained. This is important if you want the molds to be of the highest quality...Final Wet-sanding was done with 600 or 800-Grit. Mold Release wax applied to Seven Coats and buffed out between each coat. PVA is then wiped over the entire part and allowed to dry. The Part shown is the Front Valence and it's ready to make the mold now. I'll get into this process a little later in our Technical articles and ebooks.

The Primer was applied after most of the deep scratches and Pin-holes were filled with Polyester Putty and final-sanded to 100-Grit. The panels can now be cut to their Bolt-On dimensions. More filling and sanding to get the Mounting Flanges and Returns shaped and once again Primed. A guide coat is applied and final blocking is done with 320-Grit paper to all of the parts. The Pin-holes were thoroughly filled so that virtually none remained. This is important if you want the molds to be of the highest quality...Final Wet-sanding was done with 600 or 800-Grit. Mold Release wax applied to Seven Coats and buffed out between each coat. PVA is then wiped over the entire part and allowed to dry. The Part shown is the Front Valence and it's ready to make the mold now. I'll get into this process a little later in our Technical articles and ebooks.

Days,months etc. later, the final Mold is complete! Jessica is again helping out her Dad...and she's a little older now.

I had wheeled the 911 shell out on the driveway one sunny day to remove the now useless plug pieces. Just as I'm using my 2-pound Sledge some of the neighborhood kids were walking by..."Look! He's Killing the Car!"

I had wheeled the 911 shell out on the driveway one sunny day to remove the now useless plug pieces. Just as I'm using my 2-pound Sledge some of the neighborhood kids were walking by..."Look! He's Killing the Car!"With the first parts successfully made, it was time to fit and graft on the body parts. The shell had been treated with a Rust Modifier on the surface rusted areas and then sprayed with Zinc-rich Primer.

When all of the parts fitted well they were once again removed, sanded and primed with High-Solids Green Urethane Primer. I finish-sanded the Door Jambs, Inner Panels, Bolting Flanges and painted them first a Ford Cayman Blue. The Engine Bay, Bonnet and Interior were then painted Satin Black.

When all of the parts fitted well they were once again removed, sanded and primed with High-Solids Green Urethane Primer. I finish-sanded the Door Jambs, Inner Panels, Bolting Flanges and painted them first a Ford Cayman Blue. The Engine Bay, Bonnet and Interior were then painted Satin Black.The underside of the body, inner wheel arches, under the bonnet and Engine bay were sprayed with black body Schutz. All the necessary seals were filled with beads of Urethane Seam Sealer.

The 911 is starting to look pretty good now! No more scoffing, chuckling or negativity from anyone...everything was moving along smoothly and then...Oh No! I'm out of a Job. This really sucks because it was one of those 'Real Jobs' people kept talking about and now...?

The 911 is starting to look pretty good now! No more scoffing, chuckling or negativity from anyone...everything was moving along smoothly and then...Oh No! I'm out of a Job. This really sucks because it was one of those 'Real Jobs' people kept talking about and now...?To make matters worse, my 'Unique' Idea was no longer unique. On the cover of the European Car Magazine was a picture of a 959 Replica now available from a California based company. It was small consolation that my effort was better looking and detailed...theirs was Market-Ready!

This was the moment of Truth. It seemed that I may have made an expensive mistake...or did I? OK, so I missed the train on this one, but I built it with care and respect for what the 911 is, a well-built German Sports Car most anyone would be pleased to own. But is seems that the most valuable lesson was...

I learned to be Tenacious, Patient and FocusedAs my skills also increased exponentially, I also came to realize something very important that would help me in all of my future pursuits...It isn't always about the Money, it's about taking Pleasure in the Work, the money would come later.

This baby is now painted, running and has been driven from time to time. It has been written up in the PCA 'Timberline' magazine, a Porsche Enthusiasts publication and also shown at numerous events. You can well imagine that it is a very noticed car...I still own this one today and it is part of our 'Shop Furniture'.

This baby is now painted, running and has been driven from time to time. It has been written up in the PCA 'Timberline' magazine, a Porsche Enthusiasts publication and also shown at numerous events. You can well imagine that it is a very noticed car...I still own this one today and it is part of our 'Shop Furniture'.If you are interested in getting some parts to convert your 911 or would like to know more about this project, drop me a line at http://www.blogger.com/wolfzters@shaw.ca

I will be posting some more pictures of the finished car in spring. I need to give it a good clean-up. Check out my other Wolfzter Posts for more Interesting, Humorous and Inspiring tales of High-Adventure in the car business.

God Bless

Wolfzter

Labels:

Porsche 911,

Porsche 959,

Replica,

Replicas

The 427 Cobra Years...The Beginning

Unemployed, near Broke and Losing Heart! Yea, I'm over 30 now but hey, at least I have the Porsche...one dream realized at least. What am I going to do for a living? I have a Wife, two Kids, a Dog and Car Payments to make...starting to lose sleep now.

Unemployed, near Broke and Losing Heart! Yea, I'm over 30 now but hey, at least I have the Porsche...one dream realized at least. What am I going to do for a living? I have a Wife, two Kids, a Dog and Car Payments to make...starting to lose sleep now. How it it ever come to this?My Dad has been following my Porsche project closely and asked me if I could build him a Cobra Replica. I was worried about having to sidetrack one project to start on another, but it was some work after all (Family Discount, so not much Cash!).

I located an old 'Roach' of a Cobra Body with a lot of the parts missing, but the price was right. Dave and I brought home this piece and Tania started wondering again..."Is this guy ever going to quit and get a real Job?"

I located an old 'Roach' of a Cobra Body with a lot of the parts missing, but the price was right. Dave and I brought home this piece and Tania started wondering again..."Is this guy ever going to quit and get a real Job?"

I made some arrangements with another friend to use his garage to build the molds and the work began. I remember it was a hot summer in 1990 and the work went on until Fall.

I pulled the first body for my Dad's car and now possessing some Cobra Body Molds, thought I was in Business. I formed a Company and called it Can-Am Motorcars and started to advertise in the local paper as a Cobra Kit Builder...Or so I thought! Double-click the pics to get the full size.

I tracked down an old Home-made Cobra Frame through another friend and got a deal at $300 bucks. I stationed this puppy beside my emerging Porsche and also began working on it to the rolling Chassis stage...Things were starting to come together for me.

I tracked down an old Home-made Cobra Frame through another friend and got a deal at $300 bucks. I stationed this puppy beside my emerging Porsche and also began working on it to the rolling Chassis stage...Things were starting to come together for me.An older gentleman was driving by regularly and one day spotted the chassis. He stopped in and introduced himself...and decided this would be a good hobby for him in his retirement age. It seems that I have my first Sale! Wow, that really puts wind in the sails and I started putting in overtime now. I was always raised with the knowledge that Hard Work Pays off and it now seemed true to me.

I had now outgrown the Garage and needed some proper Commercial Shop space. I cooked a deal with my Dad to borrow a little of his shop in Langley. This is where we finished off the first Cobra car.

I had now outgrown the Garage and needed some proper Commercial Shop space. I cooked a deal with my Dad to borrow a little of his shop in Langley. This is where we finished off the first Cobra car.Things went well and the phone started ringing a little at a time, the only other manufacturer in the area was a guy in North Vancouver...I was not afraid of a little competition.

My Dad finally got fed up with the Fiberglass fumes and asked me to move on...well, I guess it was time anyway. I signed a lease for another shop in Langley with no real work to pay the bills, starting to lose sleep again. I had to take on any kind of work just to make my monthly payments and my wife Tania was a real help during those tough times!

With the 'Old Man's' car finally finished it was time to build our own car for demonstration purposes only (Yea, Right!). Tania says "We can't afford this right now...or ever!" I somehow convinced her that it was now or never, it will pay off in the end. A little 'Salesmanship' on my part got the nod to go ahead.

With the 'Old Man's' car finally finished it was time to build our own car for demonstration purposes only (Yea, Right!). Tania says "We can't afford this right now...or ever!" I somehow convinced her that it was now or never, it will pay off in the end. A little 'Salesmanship' on my part got the nod to go ahead. Guys, it really helps to have your Spouse on your side!Life can get quite tense otherwise. With our 'Demo' now completed and a proper Shop Environment, we can now concentrate on building Kits and Cars!

Subscribe to:

Comments (Atom)